How We're Powering Change

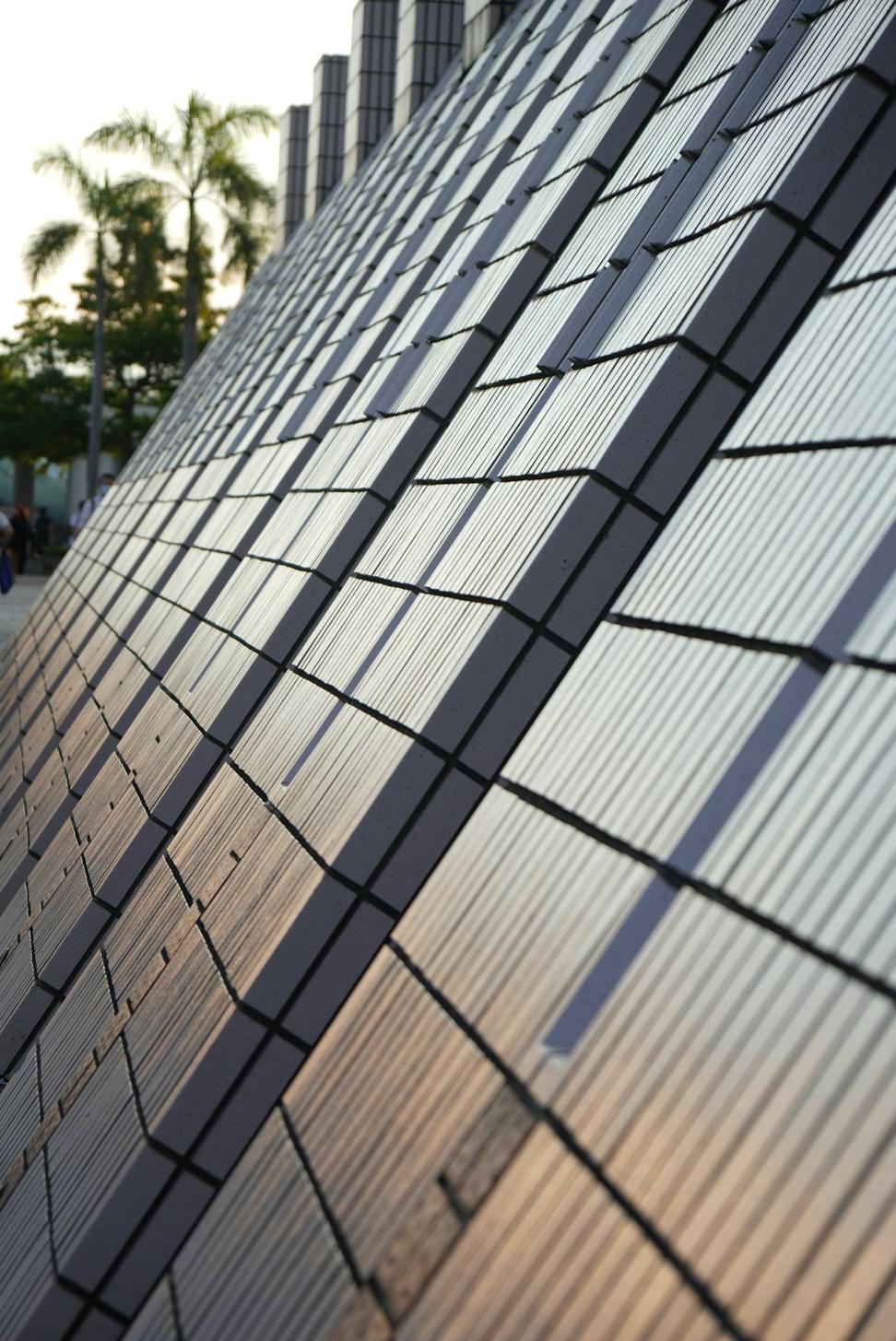

Solar Integration

68%We're obsessed with turning rooftops into power plants. Every industrial building's got that massive unused surface—might as well make it work for you.

Geothermal Systems

45%Ground-source heat pumps aren't sexy, but they'll slash your HVAC costs by half. Trust us, we've got the utility bills to prove it.

Rainwater Harvesting

82%Toronto gets plenty of rain—why let it just run into the sewer? We're capturing it for irrigation, cooling towers, and non-potable uses.

Material Reuse

91%That 120-year-old timber? It's stronger than anything you can buy today. We salvage, restore, and reimagine instead of tossing stuff in landfills.